TTCPS-001 TTCP Sensor Technology

from Tipman Corporation

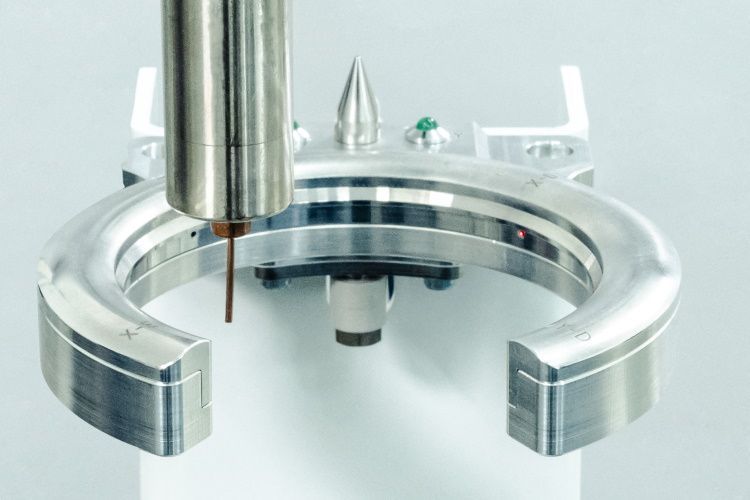

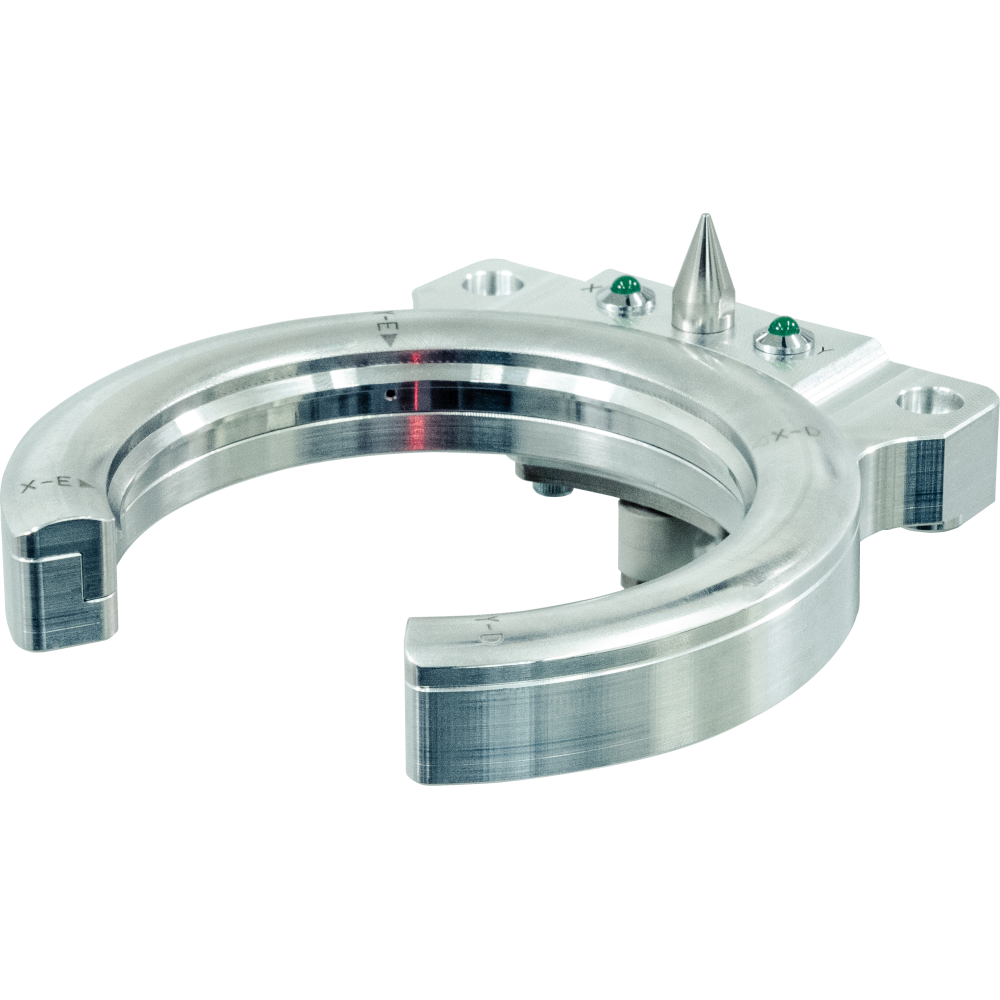

Torch misalignment creates weld defects that require expensive rework, while manual alignment checks slow down production and rely on operator judgment. Tipman Corporation's TTCPS-001 TTCP Sensor quantifies torch alignment automatically, giving you actual measurements instead of guesswork.

Our Kentucky facility started building arc welding equipment in 2003, bringing Japanese precision measurement technology to North American shops. We build equipment that catches problems before they become expensive mistakes, not after parts are welded incorrectly.

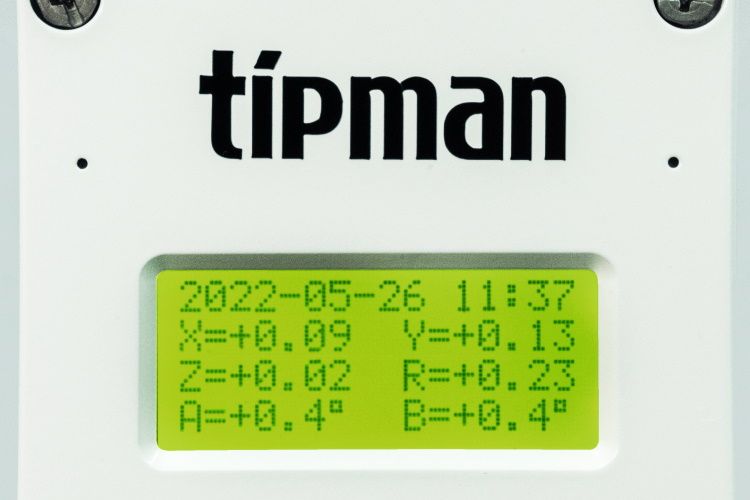

See scanned values on the controller display. An error message will occur if the scanned alignment values are greater than the set base alignment points. The error message can be found on the compatible device of your choosing, including warning lights, buzzers, robot controllers, and other devices.

Common TTCP Sensor Questions

Q: What power does the TTCP sensor need?

A: The TTCPS-001 runs on 24VDC at 0.2 amps. Low power consumption means it can run continuously without heating issues.

Q: How does the sensor store scan history?

A: Every scan is automatically saved in the onboard memory. Press the "History" button on the controller to review previous alignment measurements.

Q: What happens when alignment exceeds limits?

A: The TTCP Sensor sends error signals to whatever devices you connect—warning lights, buzzers, robot controllers, or quality management systems.

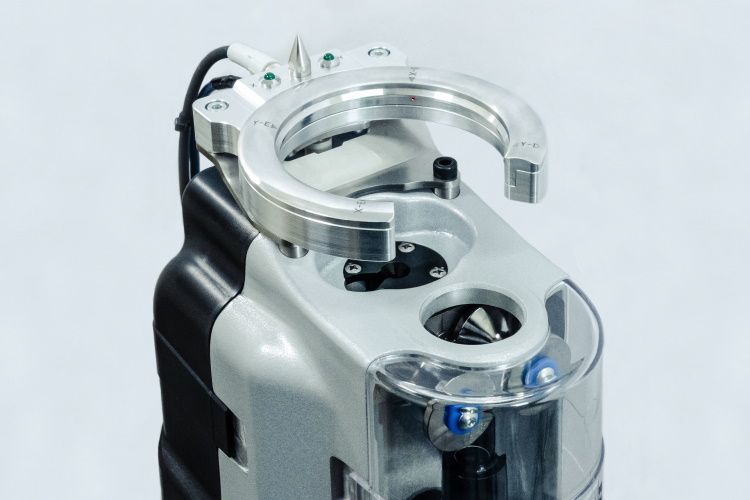

Q: Can the sensor work with our existing equipment?

A: Yes, if your robot can position the torch properly. The sensor outputs standard signals that connect to most industrial control systems.

Get TTCP Sensor Technology

For your shop

Our Kentucky team provides installation support, training, and technical assistance throughout the US and Canada. The TTCPS-001 TTCP Sensor gives you real torch alignment data instead of guesswork and assumptions.

Ready to measure torch alignment instead of guessing? Submit

our online form or call our robotic welding specialists at

(859) 800-2323. We're here Monday through Friday, 9 AM to 6 PM EST, to discuss TTCP Sensor installations.