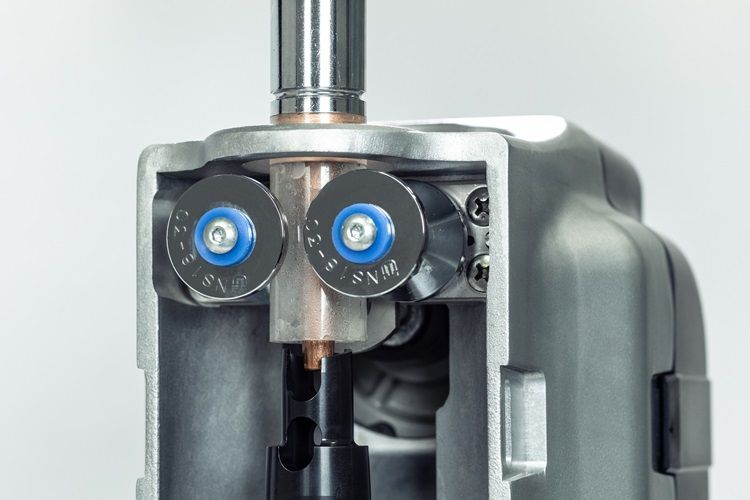

NS-01 Nozzle Station: Complete Torch Maintenance

from Tipman Corporation

Why operate three separate machines when one can handle everything? Tipman Corporation's NS-01 Nozzle Station combines wire cutting, nozzle cleaning, and anti-spatter application in a single compact unit, completing the entire maintenance cycle in just six seconds.

Since 2003, Tipman has specialized in arc welding equipment that addresses real production challenges. Our Kentucky facility brings Japanese engineering to North American markets. This welding nozzle station represents practical automation for robotic welding operations.

Lower down and reinsert the torch in the same insertion slot to spray anti-spatter liquid to the inside of the nozzle. The liquid has a mist-like texture that is well applied.

Frequently Asked Questions About Auto Contact Tip Reformer Technology

Q: How does the Nozzle Station perform three functions in six seconds?

A: The NS-01 uses optimized positioning and automated sequencing to complete wire cutting, nozzle cleaning, and anti-spatter application in one continuous cycle.

Q: What wire diameters work with this nozzle cleaning unit?

A: Approximately 40 seconds per tip, with batch processing of up to 150 pieces simultaneously.

Q: Does the Nozzle Station require special programming?

A: Integration requires basic robot positioning to align the torch with each function slot. No complex communication protocols are necessary since the unit operates independently.

Q: Can the welding nozzle station work with different robot brands?

A: Yes. The NS-01 works with any robotic welding equipment that can position the torch properly at each function slot.

Q: What maintenance does the Nozzle Station require?

A: The primary maintenance requirements are regular emptying of the spatter collection area and periodic replacement of anti-spatter liquid.

Contact

Tipman Corporation for Nozzle Station Solutions

Our Kentucky team provides installation support, training, and technical assistance across the United States and Canada. As an arc welding equipment manufacturer with decades of experience, we understand the importance of efficient torch maintenance in modern production environments.

The NS-01 Nozzle Station represents practical automation that improves consistency while reducing complexity. Instead of managing multiple maintenance stations, operators can rely on one compact unit that handles everything automatically.

Ready to streamline your torch maintenance operations? Simply submit

our online form for detailed specifications or contact our robotic welding manufacturer specialists at

(859) 800-2323. We're available Monday through Friday, 9:00 AM to 6:00 PM EST, to discuss implementing Nozzle Station technology in your facility.