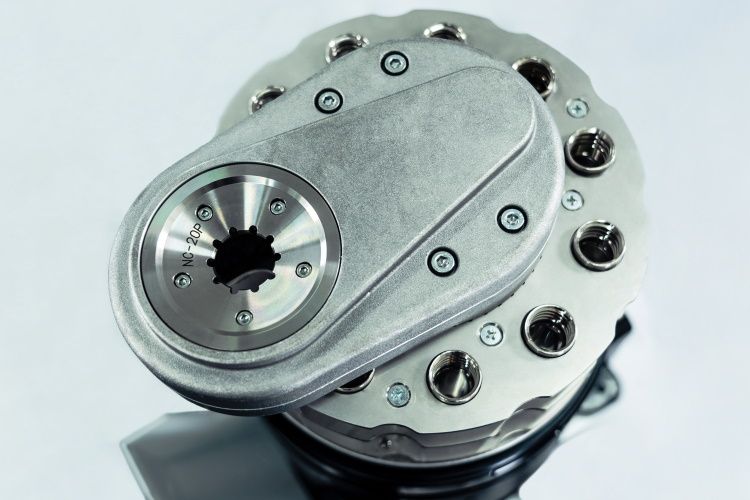

NC-002 Auto Nozzle Changer Technology

from Tipman Corporation

Why Manual nozzle replacement stops production lines and pulls operators away from other tasks. Tipman Corporation's NC-002 Auto Nozzle Changer handles nozzle swaps automatically, keeping your welding robots running while worn nozzles get replaced in the background.

Our Kentucky facility started building arc welding equipment in 2003, bringing Japanese engineering know-how to North American industries. We focus on equipment that works in real production environments, not just lab demonstrations.

Common Nozzle Changer Questions

Q: What power does the auto nozzle changer need?

A: The NC-002 uses 24VDC at 3 amps, plus shop air at 4kgf/cm². No robot communication cables required.

Q: How many nozzles fit in the magazine?

A: Ten nozzles load at once. Each replacement takes about 30 seconds from start to finish.

Q: Can the nozzle changer work with different robot brands?

A: Yes. Since no communication with the robot is required, the NC-002 works with any robotic welding equipment that can position the torch properly for nozzle access.

Q: What happens to worn nozzles after replacement?

A: The auto nozzle changer automatically ejects worn nozzles into a collection area, keeping the work environment organized and facilitating easy disposal or recycling.

Get Nozzle Changer Technology

for Your Shop

Our Kentucky team helps with installation, training, and ongoing support throughout the US and Canada. Twenty years of arc welding equipment experience taught us that simple, reliable designs work better than complicated systems. The NC-002 proves that point every day in automotive plants and fabrication shops.

Ready to stop manual nozzle changes? Submit

our online form or call our robotic welding specialists at

(859) 800-2323. We're here Monday through Friday, 9 AM to 6 PM EST, to discuss nozzle changer installations.