Auto Contact Tip Changer Solutions

from Tipman Corporation

Production downtime costs money. Every minute spent manually changing contact tips represents lost output and reduced efficiency. Tipman Corporation's Auto Contact Tip Changer eliminates this problem by automating the entire replacement process without stopping your production line.

Tipman specializes in arc welding equipment development. Established in 2023, our Kentucky facility brings decades of Japanese precision engineering to North American markets. We understand what robotic welding equipment users need: reliability, speed, and minimal disruption.

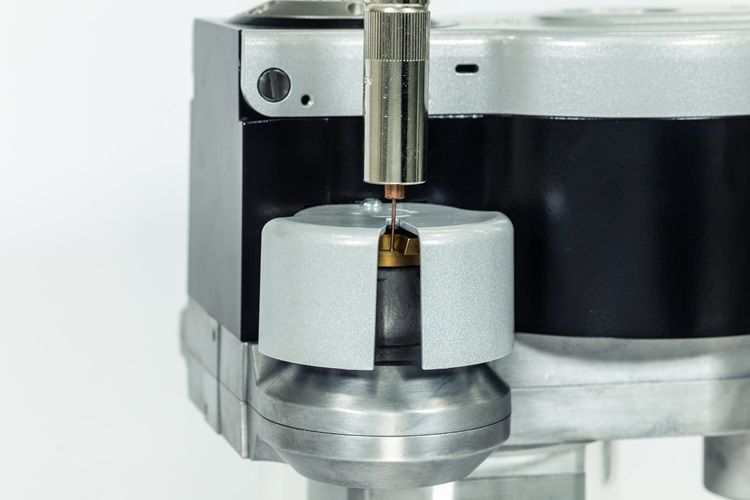

Once a new contact tip is inserted, it is screwed on, rotating until the specified torque is reached. 10 contact tips can be loaded at one time.

The nozzle is reattached and rotated until the specified torque is reached. This entire process is automated, so you can rest assured that the tip and nozzle are correctly tightened.

Frequently Asked Questions About Auto Contact Tip Changer Systems

Q: What contact tip types work with the CTC-001?

A: The automatic contact tip changer handles various standard contact tip designs. The system accommodates different sizes and thread patterns through magazine adjustments.

Q: How does the system know when to change contact tips?

A: The Auto Contact Tip Changer operates on programmable cycles based on arc time, part count, or quality parameters. Operators set replacement intervals based on their specific applications.

Q: Can the contact tip changer work with our existing robots?

A: Yes. The CTC-001 integrates with standard robotic welding equipment from major manufacturers. Installation requires minimal modifications to current setups.

Q: What happens if a tip change fails?

A: The system includes error detection and recovery procedures. Failed operations trigger alarms and stop the process until operators can address the issue.

Contact

Tipman Corporation for Auto Contact Tip Changer Solutions

Our Kentucky team supports customers across the United States and Canada with installation, training, and technical assistance. The CTC-001 Auto Contact Tip Changer represents practical automation that pays for itself through reduced downtime and labor costs.

Ready to eliminate production interruptions? Contact our automotive welding equipment specialists at (859) 800-2323 or email info@tipmancorp.com. Submit our online form for detailed specifications. We're available Monday through Friday, 9:00 AM to 6:00 PM, EST to discuss implementing Auto Contact Tip Changer technology in your facility.